Amidst the crazy moving and office renovations, I finally set my task list in order and start making a kit proper. Perhaps aided by the relative quiet of an intern-free office, and the sparseness of the new concrete-floor, high-ceiling, converted-warehouse hipster new office, I have a working prototype out.

The idea: automata are fascinating, but how about making them entirely automated! I mean, it’s fun to crank the lever but hello~ their name already belies their purpose. After a first run with Nope Sheep below, I decide a microbit powered automaton is a decently fun project that could be done in an afternoon, and I dive back into my paper-crafting roots.

This automaton was a free download from the amazing Keisuke Saka. It’s actually called the Stray Sheep, which also coincidentally happens to be the name of the pub in a video game I obsessed over for a while.

So now I have to come up with my own huh. What makes a nice animated tableau? Lines of middle-aged folk slowly moving in line at Singapore Pools? Old folk eating packed chicken rice at political rallies? The occasional bird cawing at Hong Lim park? Ok, sorry, I’ve been reading Charlie Chan Hock Chye. What exactly is kid-friendly and relevant? I’m afraid I’m getting old.

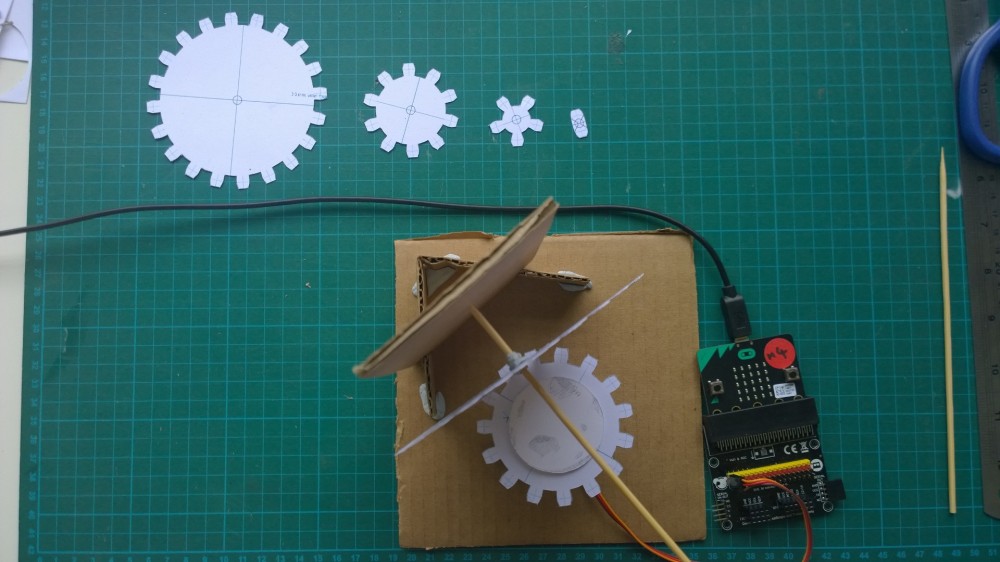

Heck, let’s just go with something that’s customizable/change-able. Hey, what about playing with gears too? I was always fascinated with gears and their teeth dictating relative speed and all.

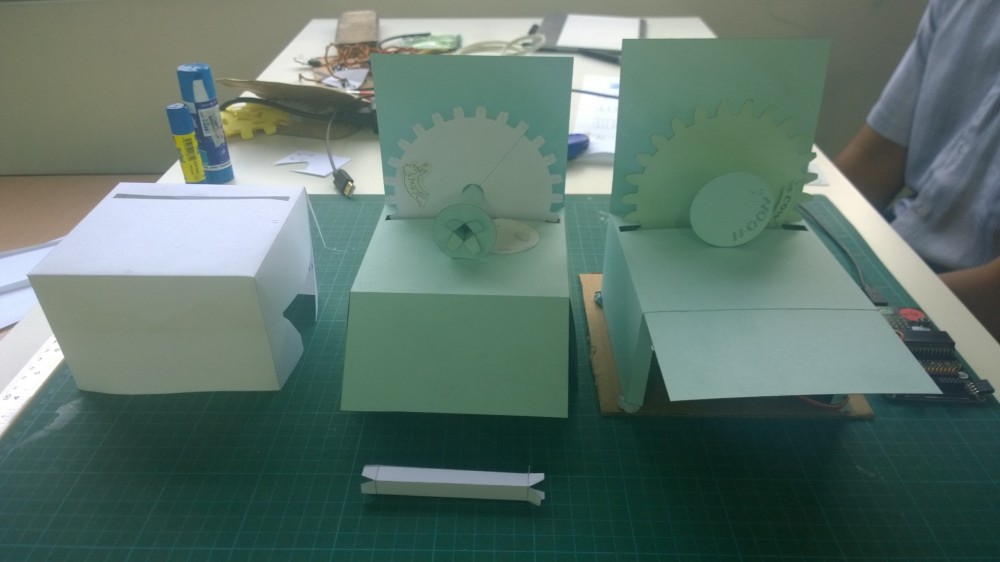

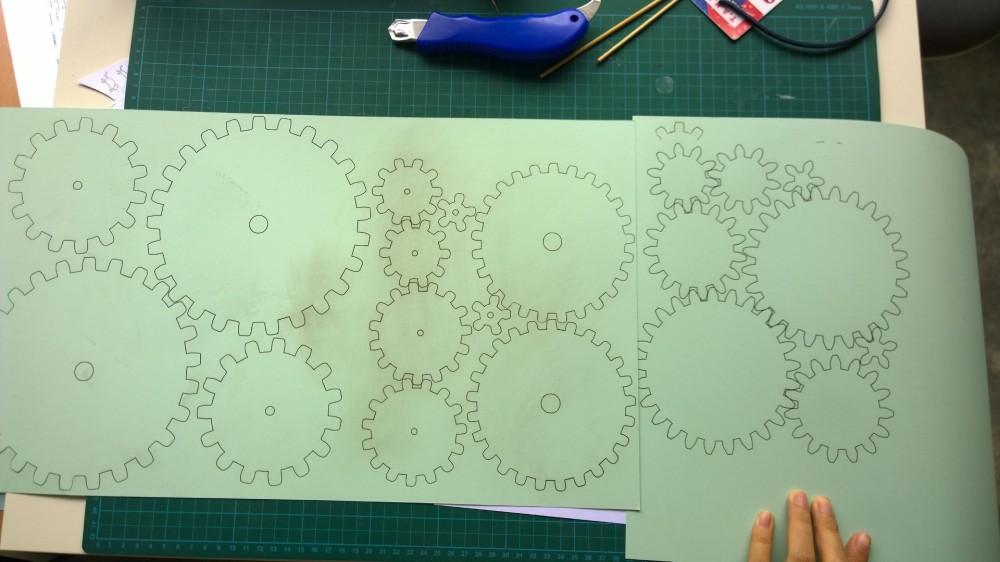

And so goes the messy process of hand-cutting, pasting, fitting, measuring, finding out my measurements are off, whaaat!?, more cutting, more pasting, more fitting. You should use the laser cutter says Steven. I spend an entire morning figuring out settings, trying to laser-cut from pdfs, crudely extracting svgs from pdfs, finding that my laser cut gears are not only ugly but also immensely huge. More time on scaling and cleaning svgs, positioning gears to waste as little paper as possible, ah what is this, it’s so much easier to cut by hand. Until Steven says there is probably a gear generator online that is much more svg friendly than the one you’re currently using. Ah, there is. Why didn’t I think of looking for that sooner, software inertia is real.

So for the latest prototype, I’m really trying to get it to be more reliable instead of jumping off the bottom gear every so often. The first prototype was made in 160gsm paper, and the latest is a double-stacked vanguard sheet. The thickness and hardness seems to be working so far, although there’s some beef with it being a little jerky. Badum tss~

The little progressions help, so you don’t get tired from multiple small setbacks. It really is the little things that count eh? Whether in the negative or the positive. Heard that it might be used for a workshop some time. But the laser-cut soot is a problem, Joey (our part-time kit-maker, crafter, littleBits explorer) mentioned that parents would definitely be unhappy with residual soot on the edges of these laser-cut objects. Is it our laser-cutter, or is it just inevitable when lasering paper? We’re going to be getting a new air filter so I guess we’ll figure out!

Well that’s all I have for now, I’m really glad to be back working with paper. It’s such a lovely, malleable, re-usable, recyclable material. The only problem is what to do with all the prototypes when I’m done?!?!